Whether you cut thick or thin metal sheets, large or small batches—we’ve got you covered. We’ve designed four machine series to meet all types of production needs, always aligned with the highest manufacturing standards, so you can choose the best fiber laser cutter for your specific line of work.

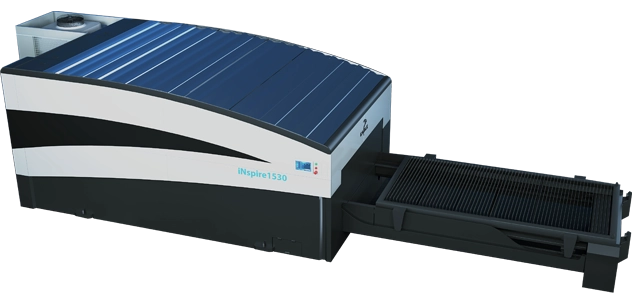

The iNspire is our flagship series and the epitome of innovation—an industrial laser cutting system designed for applications where speed, power, precision, and peak efficiency are essential.

As a high-power fiber laser cutter, the iNspire offers cutting powers ranging from 2kW to 40kW and acceleration of up to 6G, delivering the highest performance available on the market.

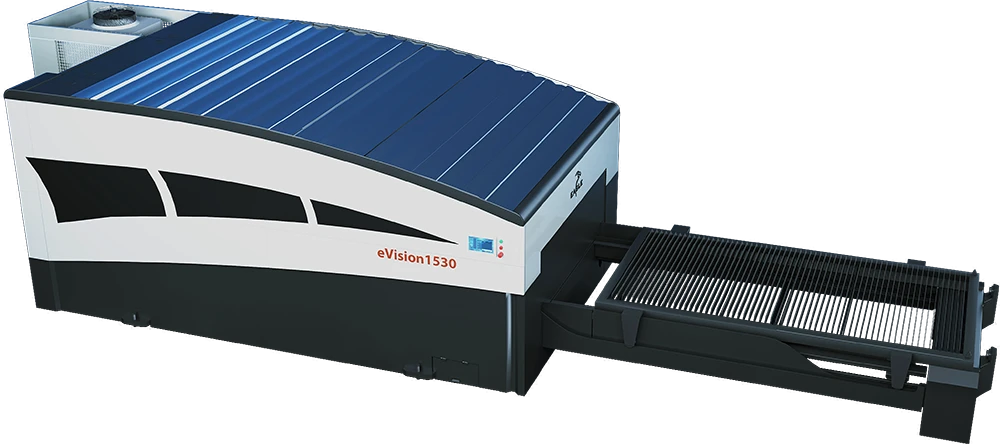

The eVision series is a high-speed laser cutter designed for all-round versatile efficiency, delivering optimal results 24/7—whether you’re processing small or large batches, thick or thin sheet metal.

A powerful CNC fiber laser cutter, it offers wattages from 2kW up to 40kW and acceleration up to 3G, making it the ideal choice for those looking to upgrade from older technologies or replace underperforming machines.

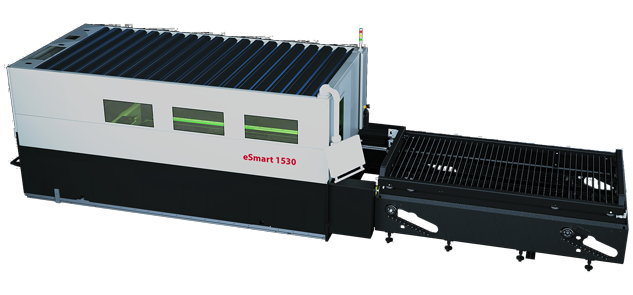

The eSmart series are industrial laser cutting systems designed for trouble-free, reliable production. These sturdy machines offer power levels from 2kW to 10kW and acceleration up to 2G. Their compact yet robust construction delivers efficiency, precision, and value making them the best fiber laser cutters for thin to medium thickness metal sheets.

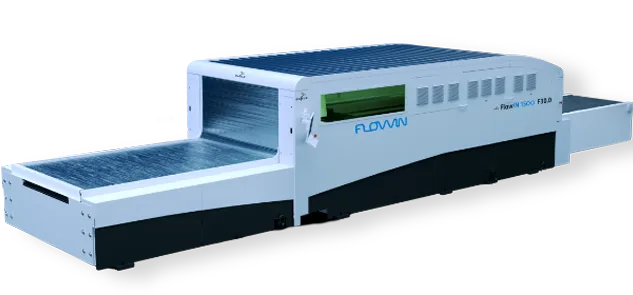

FlowIN is the first integrated industrial laser cutting system that makes sorting at the speed of cutting possible. Its groundbreaking approach focuses on cutting the scrap around the part and simultaneously managing waste. This high-speed laser cutter is ready for metal sheets or coil and ensures only scrap-free parts exit the machine, optimizing manual or automatic sorting.

The model and power of the CNC fiber laser cutter that’s best for you will depend primarily on the volume you process, the range of material thicknesses, and your company’s growth projections. An industrial, high-performance laser cutting system is a major investment, and we’re here to help you make an informed decision. To simplify the process and ensure confidence in your choice, consider these six key points:

For thin metal sheets 6 mm and below you won’t need a fiber laser cutter with powers above 10kW and should focus more on acceleration parameters. If you cut thicker plates from 10 mm to 40 mm it’s best to consider powers 15kW and above which will provide you with higher cutting capacity.

Consider the average sheet size you process the most and make sure the CNC fiber laser cutter will be able to accommodate it. If you plan to expand your range of products, choose a table size that will allow for this growth. At Eagle we offer larger than average cutting tables reaching 3 m x 16 m

If high speed is essential, you’ll want to choose a fiber laser cutter with high acceleration (G-force) capabilities. While power is more relevant for cutting thicker sheet metal, acceleration becomes the key factor when working with thin sheets. When all other parameters are equal, the machine with the highest acceleration will always be the fastest.

Make sure the machine you choose includes process optimization software to enhance every aspect of your CNC fiber laser cutter—from industrial process monitoring to improved cutting speed and edge quality. Look for a laser cutting system that ensures seamless integration with automation solutions, allowing you to fully maximize its cutting potential.

In today’s industrial landscape, where skilled workers are increasingly scarce, user-friendliness is essential—along with accessibility, ergonomics, and operator safety. The more intuitive the machine’s control panel and HMI, the easier and faster it will be for both experienced and new operators to understand and operate the fiber laser cutting system.

If you aspire to increase your product/service portfolio in the future and purchase a CNC fiber laser cutter to cover only your current needs, you may find yourself needing a more efficient one soon. Take your expansion into consideration to make a long-lasting investment.