With us, you receive a complete package to elevate your metal cutting capabilities from a single provider. From fiber laser cutting machines built in the EU with the highest quality components, to automation systems, and process optimization software. Eagle’s Industry 4.0 laser cutting solutions optimize workflow and enhance productivity.

Built for Last. Proven for profit. Eagle combines record-setting performance with real-time transparency and a fully integrated ecosystem —so every shift runs faster, cleaner, and more predictably.

Cut more parts per hour — every hour. Our high-power fiber lasers, unique machine construction, and ultrafast motion dynamics shorten cycle times across thin-to-thick materials. Shorter pierce times, faster and more reliable changeovers, and optimized cutting paths mean lower energy and gas consumption, and a consistently lower cost per part.

Eagle Trust embodies our customer-centric philosophy through fairness, reliability, and trustworthiness. See how your system is performing in real time through MyERS, send and track service requests with MyESP, and order spare parts conveniently through Machine Portal. Optimize your process — the Eagle way.

Everything you need from one provider. From sheet cutting to automated loading/unloading and storage, from coil feeding to automatic part separation and sorting — Eagle keeps material moving while our software manages nesting, scheduling, and diagnostics. Every element is designed to deliver peak efficiency and support your growth.

For over two decades, we’ve pushed the boundaries of fiber laser–cutting technology through superior construction and a groundbreaking design philosophy. Today, we continue to redefine what’s possible, driven by one core mission: enabling you to produce more parts faster, safer, and with higher profits.

Book a live demo or send your drawings for a tailored cut test—and see how Eagle turns sheet metal into finished parts, faster.

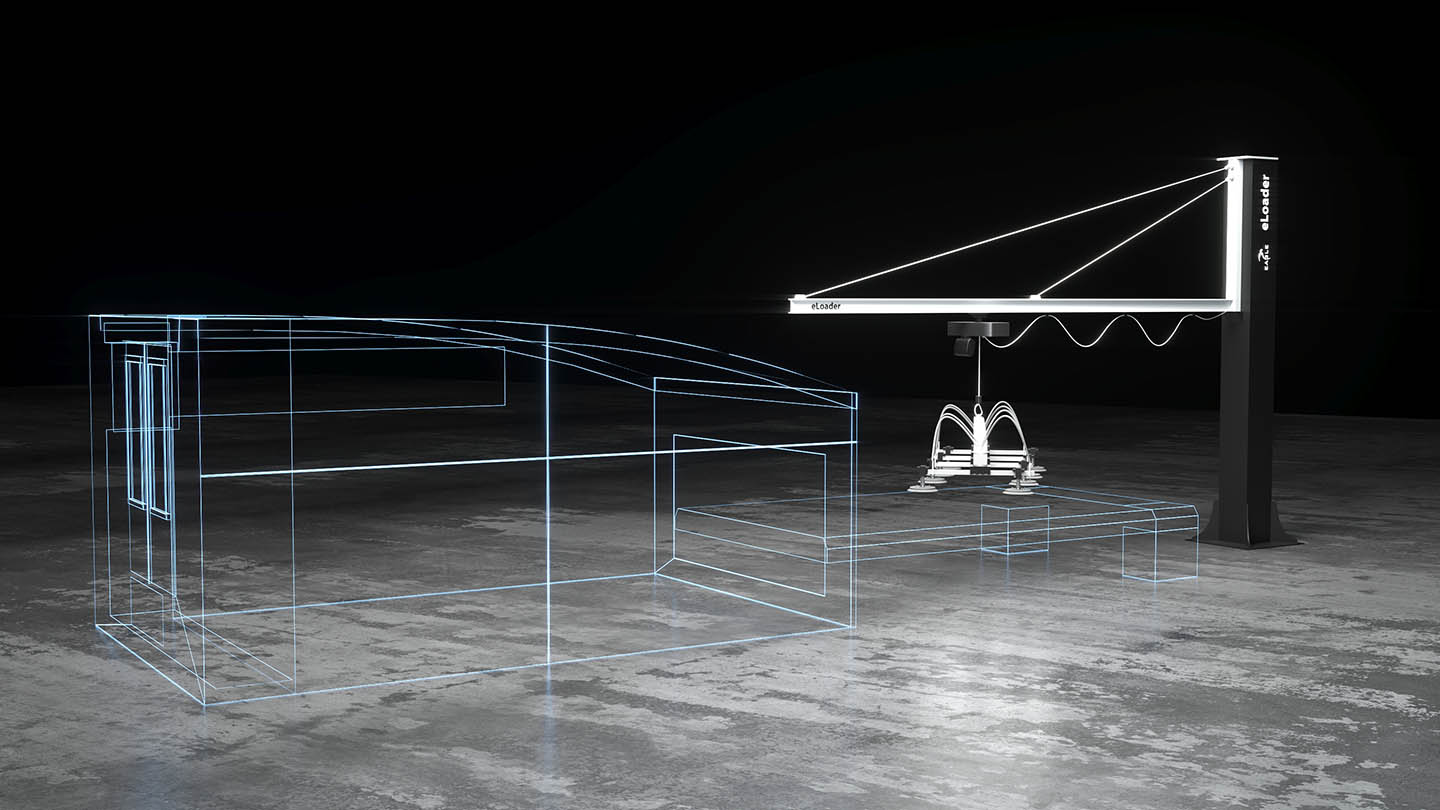

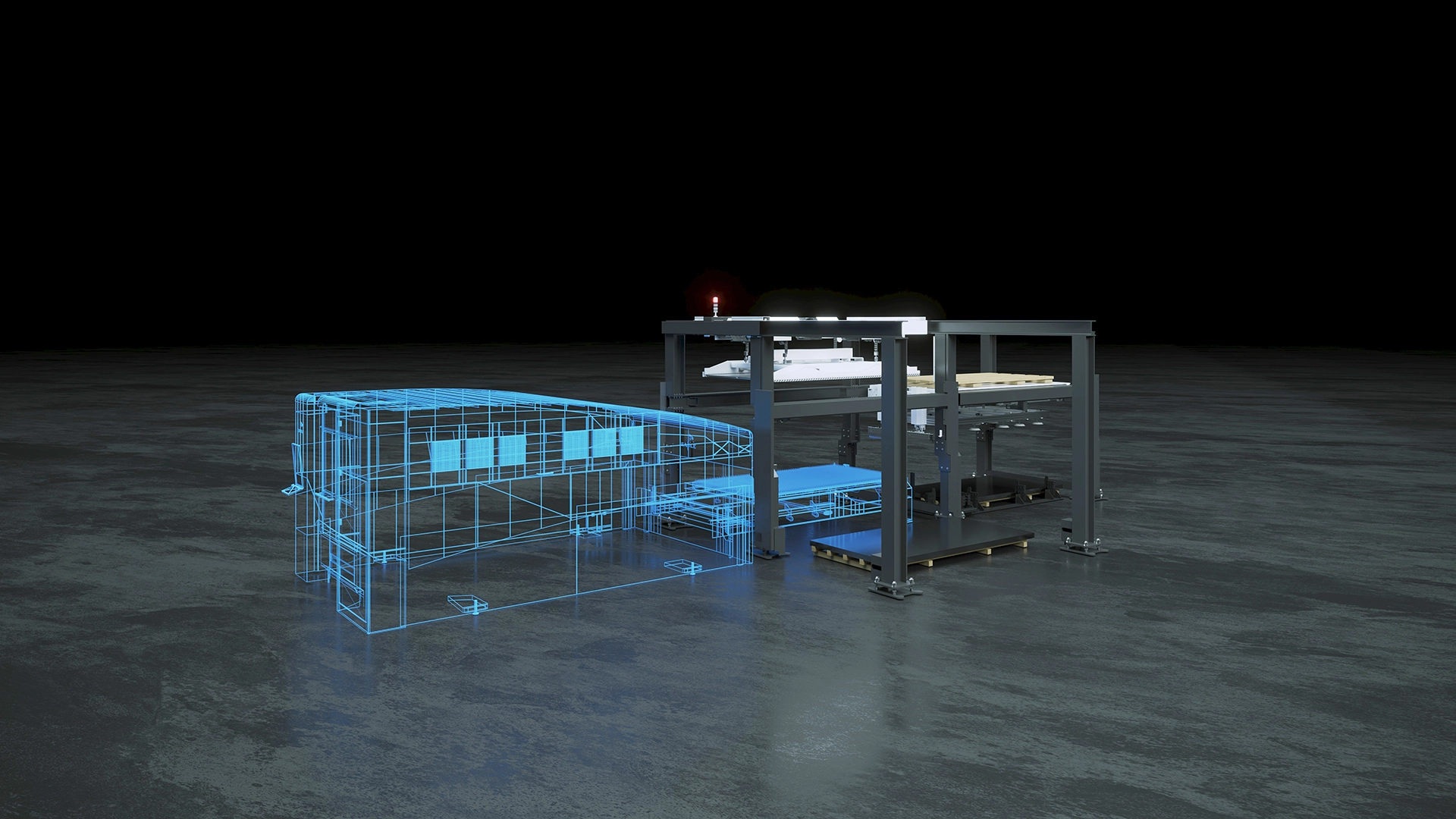

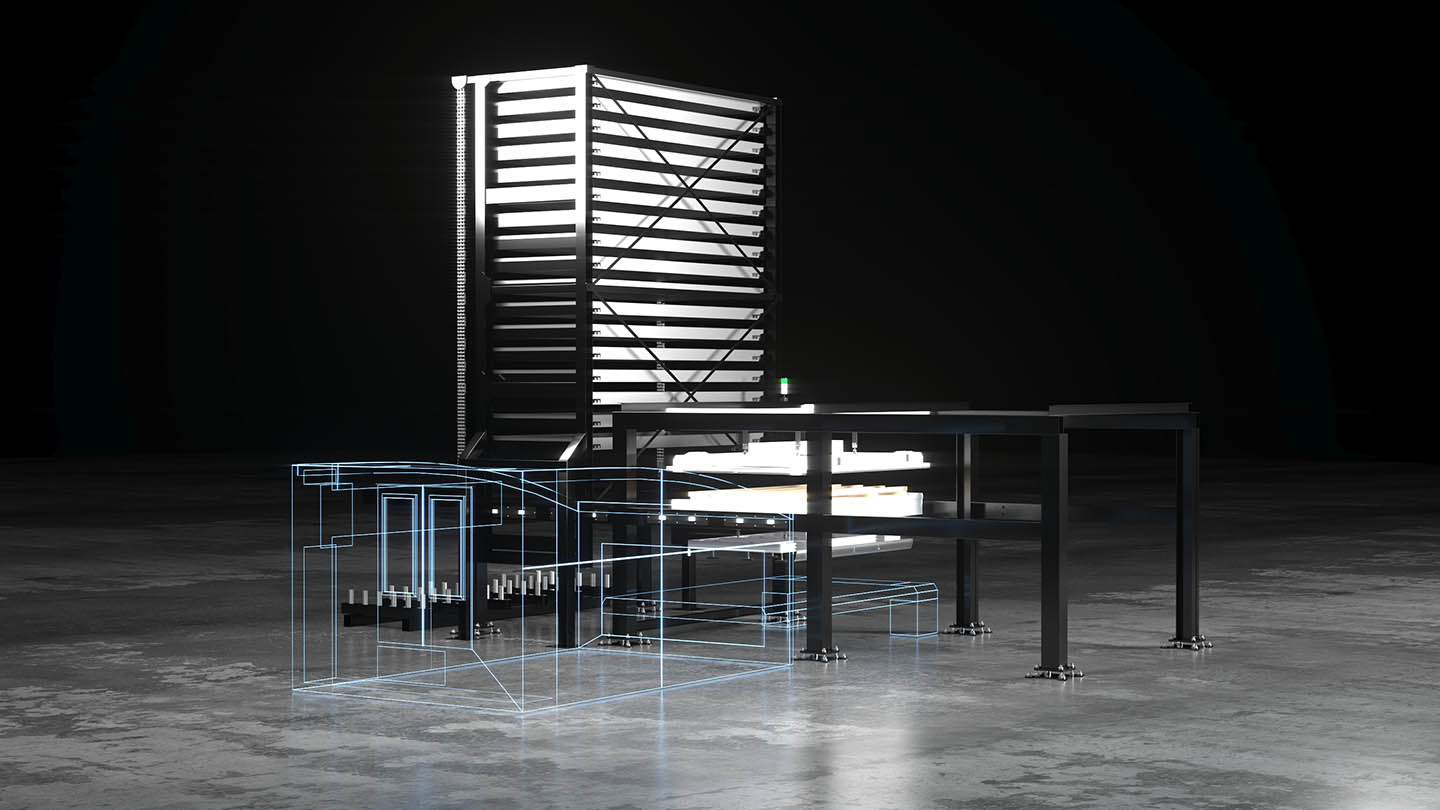

BOOK A VISITEnhance your fiber laser cutting machine’s capabilities with our modular automation systems

This option is designed for shops focused on improving safety, reducing physical strain, and achieving quick effciency gains without a full-scale investment.

This option provides a complete solution for continuous, high-volume production, maximizing the throughput of the laser cutting machine during regular shifts.

This is the ultimate solution for high demanding productions, designed for maximum profitability through "lights-out" operation and optimized material and storage logistics across the entire facility.

Smart loading/unloading, eTower/FlowStore, coil-feed, and FlowSort keep material moving with minimal touchpoints —cutting idle time, changeovers, and bottlenecks.

Automated handling and sorting reduce manual steps and rework, shrink work-inprocess, and stabilize cycle times—driving down unit cost.

Machine, automation, and software designed by a single manufacturer to work together flawlessly — no mismatches, faster setup, and cleaner data from day one.

We offer the most rigid structures and the most versatile configurations, allowing you to scale and expand by adding more modules as you grow.

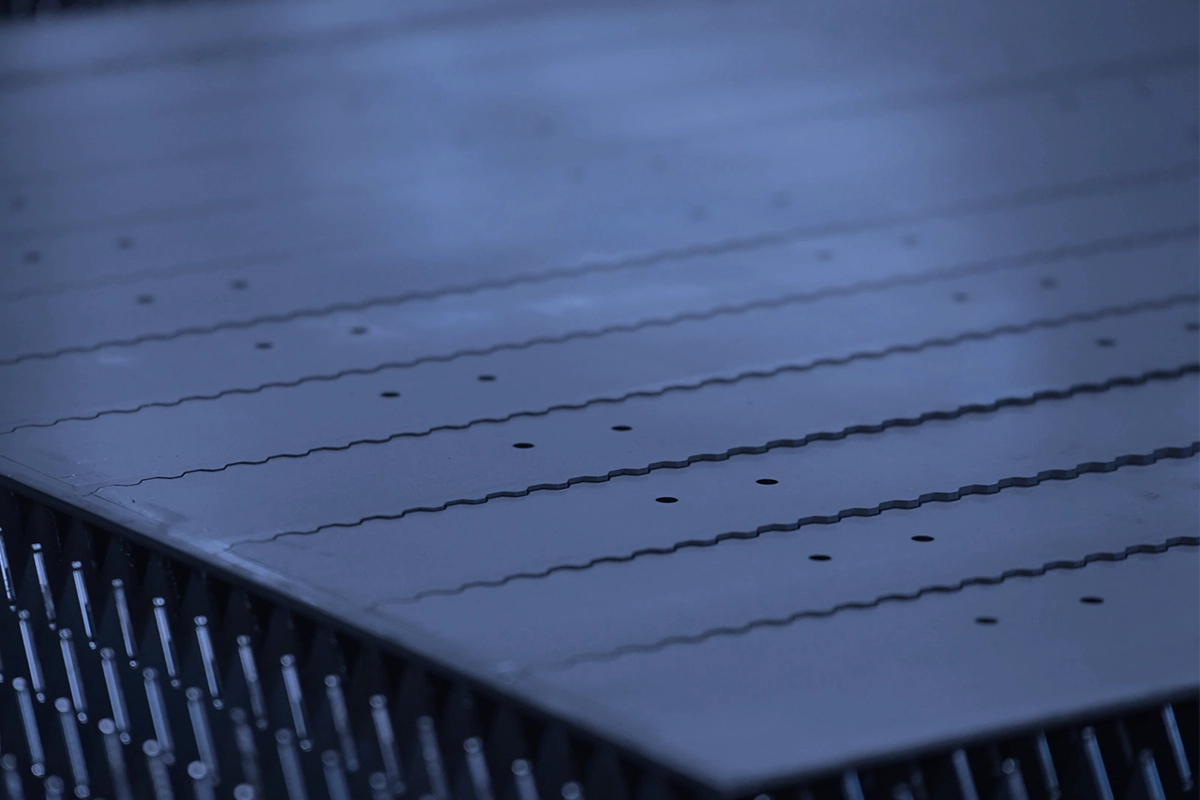

Our optimization software and technology are the result of extensive research, testing, and trials, all aimed at enhancing every aspect of the metal cutting process.

We provide proprietary solutions that increase cutting speed, optimize gas usage, expand thickness capabilities, and improve edge quality.

Additionally, in alignment with Industry 4.0 solutions, our software is designed to monitor the entire production process, provide operators with an intuitive user interface, and remotely detect errors—ensuring seamless and efficient laser cutting operations.

Every advanced laser cutting operation needs intelligent software to stay ahead. Eagle’s solutions help you monitor your production flow, optimize processes, spot inefficiencies, and maximize performance while preventing errors and reducing downtime.

If your production includes thin to medium metal sheets, Eagle’s advanced software is designed to boost laser cutting and piercing speeds, reduce cycle times, and help you achieve higher throughput with better margins.

If you work with medium to thick sheets or plates, Eagle’s metal cutting optimization software is built to increase speed and cutting quality, minimize burr, reduce gas consumption, and maximize laser performance.

Whether you’re laser cutting thin, medium, or thick materials, this advanced software lets you cut single parts from sheet remnants without creating a new program. Maximize your material usage, minimize waste, and save valuable time.