For industrial-scale manufacturers or high demands production companies, relying on daytime shifts or manual logistics is a significant competitive disadvantage. This solution is the culmination of sheet metal automation, designed not just to speed up the cutting process, but to optimize the entire material flow of your facility. It’s about leveraging the speed of your EAGLE laser around the clock, converting non- operational hours into highly profitable production time.

The CraneMasterStore is a loading and unloading system designed for seamless integration between material storage tower systems and the cutting machine.

It delivers all the functionalities expected from the CraneMaster line—including efficient loading of material from the warehouse to the cutting machine and simultaneous unloading of cut parts back into the warehouse or onto an unloading station.

This advanced laser cutting automation system enables fast material exchange and storage, supporting fully automated logistics. It is ideal for high-performance manufacturers with medium to high production volumes.

The CraneMasterStoreLinear is a highly efficient loading/unloading system designed for seamless integration between material storage towers and the cutting machine. It delivers all the automatic functions of the CraneMaster. With two vertically mobile pallets that can move freely within the structure and be placed directly on the floor, it offers exceptional flexibility. Loading and unloading stations can be positioned on either side of the machine, adapting to your layout needs. This makes it the most versatile laser cutting automation system in the CraneMaster family and ideal for manufacturers with medium to high production volumes.

SEE IT IN MOTION

The eTower1 is a single-tower storage system for sheet metal processing equipped with a loading/unloading station and universal shelves that can hold raw material, cut parts, or remnants. It includes a transport column with a lift that moves pallets between the shelves and the loading/unloading station.

The standard eTower1 is available with 10, 15, or 20 shelves, but it can be customized to meet specific needs. It also features a control panel for managing material storage and retrieval throughout your facility.

The CraneMaster systems and eTower1 work in tandem, enabling 24/7 unattended production and maximum productivity.

SEE IT IN MOTION

The eTower2 is a two-tower warehouse system equipped with a loading/unloading station and universal shelves designed to hold raw material, cut parts, or remnants. It features two transport columns with lifts that move pallets between the shelves and the loading/unloading station.

The standard eTower2 system comes with 26, 36, or 46 shelves, but it can be customized to meet your specific requirements. A built-in control panel enables efficient management of material storage and retrieval across your facility.

The CraneMaster systems and eTower2 work seamlessly together to optimize process logistics, enabling unsupervised material handling for laser cutting and the highest productivity

SEE IT IN MOTION

The eTower X2 is an extended dual-tower storage system for sheet metal processing that requires higher capacity and optimized space utilization. It features two towers arranged in a linear configuration, delivering increased storage volume while ensuring smooth integration with loading and unloading systems.

The eTower X2 includes a transport column with a lift that moves pallets between the storage shelves and the loading/unloading station. The system is fully compatible with CraneMasterStore and other automation modules, enabling seamless handling and storage of raw sheets, cut parts, and remnants.

The eTower Q4 is a high-capacity automated storage solution featuring a four-tower configuration, ideal for manufacturers handling large-scale production volumes. With its expanded structure, the eTower Q4 offers maximum storage density, while maintaining full compatibility with loading and unloading systems.

The eTower Q4 features a central transport column with an integrated lift that transfers pallets between storage shelves and the loading/unloading station. The system enables efficient handling and storage of raw sheets, cut parts, and remnants, and is fully compatible with the CraneMasterStore modules.

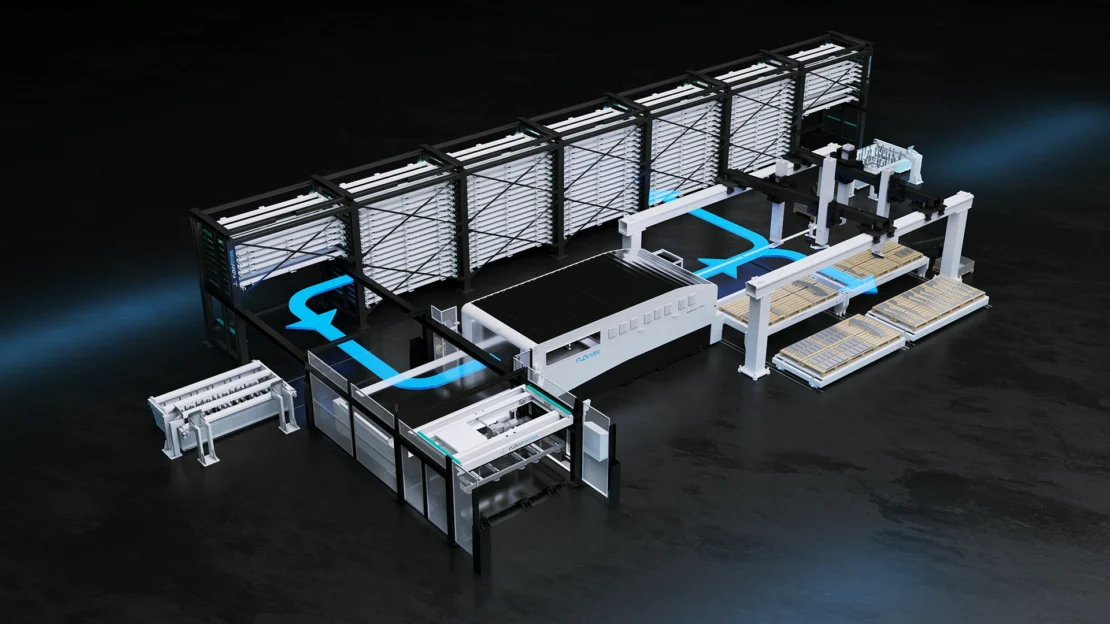

The Eagle Stacker Solution is a high-capacity storage system for sheet metal processing, designed for production facilities that demand exceptional operational efficiency and optimal use of storage space. Built on a robust, scalable multi-tower configuration, it offers virtually unlimited expansion to support high-volume operations and diverse material formats.

Fully compatible with Eagle’s automation modules—such as CraneMaster and CraneMasterStore—the stacker enables automated pallet handling, efficient part flow, and secure storage of raw sheets, finished parts, and remnants.

In an industry where margins are tight and speed is paramount, your laser cutter is your most valuable asset—but is it operating at full capacity? The moment you install an EAGLE laser, your production focus must shift from cutting speed to material logistics.

The EAGLE Modular Automation systems do more than just manage material; they integrate every single part of your supply chain, creating a seamless, intelligent flow. This is the difference between running a fast machine and running an optimized factory , offering you a transformative structural enhancement that guarantees a measurable Return on Investment (ROI).

Modularity is the key to having the best solution for your specific needs, and EAGLE is one of the few

companies offering such a huge variety of scalable, deeply integrated solutions.

Modularity is the key to having the best solution for your specific needs, and EAGLE is one of the few companies offering such a huge variety of scalable, deeply integrated solutions.

The EAGLE modular system transforms your material stock from a passive asset into a profit-generating engine by enhancing visibility and dramatically cutting waste.

The CraneMaster systems act as the high-speed connector between storage and production, built for seamless and relentless operation that maximizes the potential of your laser

Reliability is built into the framework of EAGLE automation, ensuring maximum uptime and long-term durability. The result is a more stable, predictable, and reliable production environment.

EAGLE offers a vast range of solutions that convert into a comprehensive, adaptable modular system for every shop floor. This adaptable approach guarantees the perfect fit for your budget and space constraints. From the layout to the number of towers, EAGLE’s modular system is the solution.

Marzee specializes in custom metal fabrication and job shop services, cutting materials such as aluminum, stainless steel, steel, and copper. By upgrading from waterjet cutting to two high-power Eagle fiber laser cutting systems, they have:

From fiber laser cutting machines to automation systems and advanced software, get an in depth view of all Eagle products by downloading our brochure.

download our brochure