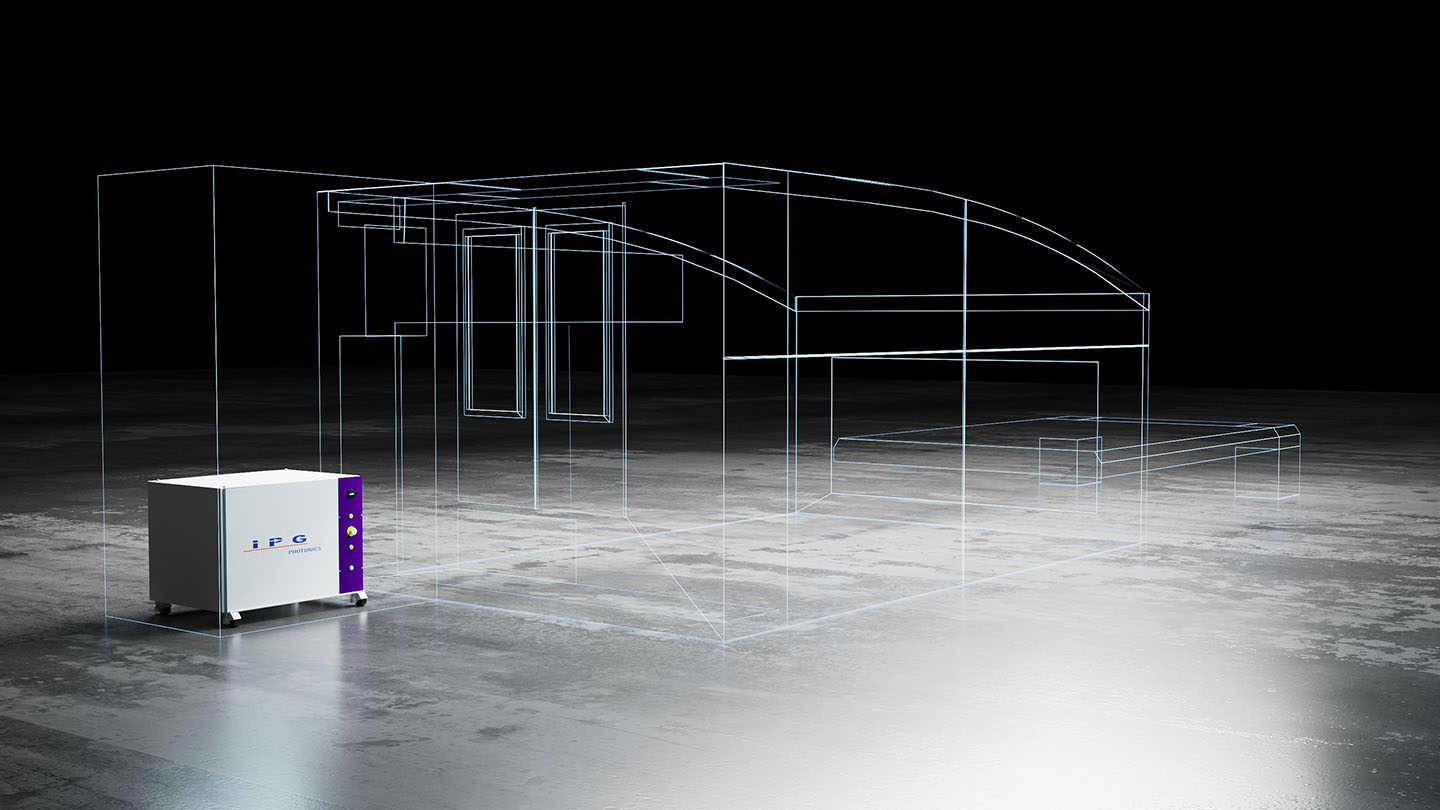

At the heart of every Eagle machine is IPG Photonics—the global standard for fiber laser power, reliability, and efficiency. When motion is extreme and precision is non-negotiable, the source must keep up.

Every Eagle fiber laser cutting system is powered by IPG Photonics laser sources—the global benchmark for efficiency, reliability, and high-power. Cutting performance isn’t defined by watts alone, but by how precisely, consistently, and rapidly that power is delivered to the cut. IPG sources offer exceptional beam stability and ultra-fast power modulation, enabling Eagle machines to accelerate harder, pierce faster, and cut cleaner, without compromising edge quality or process stability.

To match each machine’s performance envelope, Eagle integrates the appropriate IPG platform. Compact and efficiency-focused systems use YLR (Ytterbium Laser Rack) sources, ideal for thin-to-medium sheet processing with outstanding energy efficiency. High-performance machines from 12 to 40 kW are equipped with YLS (Ytterbium Laser System) sources, engineered to reliably deliver and sustain extreme power levels in demanding production environments.

Eagle machines are designed for peak motion dynamics, continuous operation, and long-term reliability. The laser source must perform at the same level. IPG Photonics leads the industry in electrical-to-optical efficiency, thermal stability, and source longevity—critical factors when machines operate at high acceleration, high duty cycles, and maximum power. Combined with Eagle’s composite machine body, linear motors, and advanced motion control, IPG sources ensure cutting speed translates into real throughput, consistent quality, and low cost per part. shift after shift.

As the world leader in fiber laser technology, IPG continues to redefine what’s possible in industrial laser cutting. Their decades of expertise and continuous innovation align perfectly with Eagle’s Ideal Machine Concept, delivering power you can trust, performance you can exploit, and reliability built for long-term production.