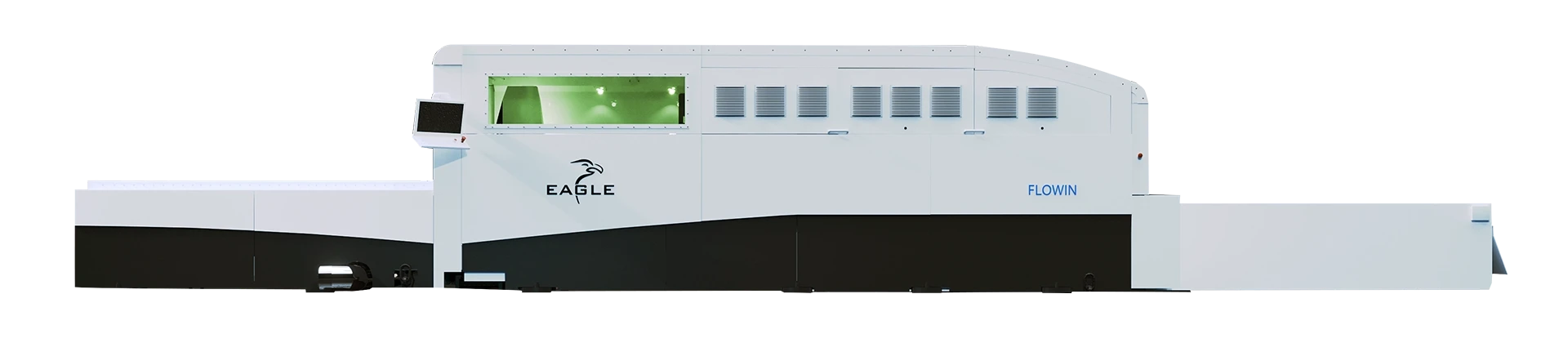

FlowIN isn’t an upgrade, it’s a new way of thinking about laser cutting. By reimagining how parts are separated from scrap, FlowIN eliminates one of the biggest bottlenecks in sheet metal production. Cutting, separation, and waste handling happen in one continuous flow, delivering higher productivity without compromising nesting efficiency or cutting speed.

FlowIN is a new category of fiber laser cutting systems, designed to integrate cutting, part separation, and scrap management into one continuous process.

| BASE DATA | |

|---|---|

| Laser sources: | up to 40kW |

| Acceleration* | up tp 6G |

| Accuracy | 0,05 mm |

| Top cutting speed | 150 m/min |

| Top positioning speed** | 400 m/min |

*Top speed value is dependent on the machine’s working area.

**Top acceleration value is dependent on the machine’s working area.

FlowIN is a breakthrough fiber laser cutting concept that solves the sorting issue through a disruptive approach: Instead of focusing on cutting the part, we focus on cutting the scrap around it. The result? Ready cut and sorted parts free from the surrounding metal scrap.

Through this revolutionary process, FlowIN frees the part from the skeleton and manages waste without compromising the fiber laser cutting speed.