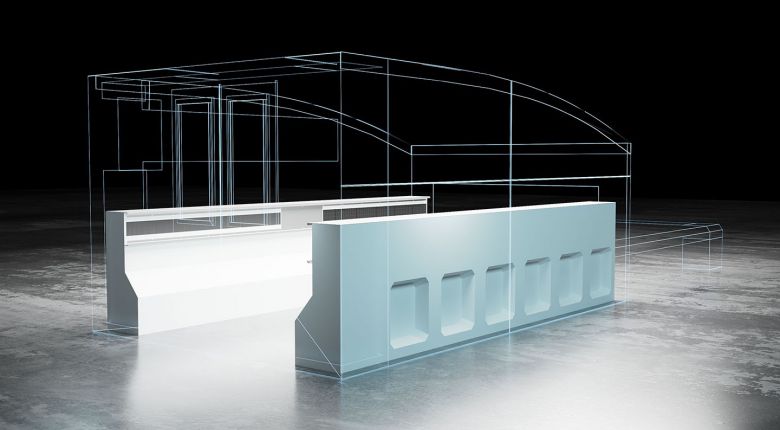

High performance demands an unshakable foundation. Eagle’s composite machine body ensures the stability and accuracy needed to fully exploit high power and extreme motion dynamics.

In high-performance fiber laser cutting, stability is non-negotiable. To maintain accuracy at extreme speeds and accelerations, the machine body must remain rigid, vibration-free, and thermally stable under constant dynamic loads.

All Eagle fiber laser cutting machines are built on a polymer concrete composite body—an advanced material combining resin binders with mineral aggregates such as granite and quartz. Compared to steel, this composite delivers up to 100× higher vibration damping and a 10× lower thermal expansion coefficient, creating an exceptionally stable foundation for ultra-fast linear motors and high-precision motion control.

This superior vibration absorption and thermal stability allow Eagle machines to sustain peak dynamics without compromising accuracy, edge quality, or repeatability. Manufactured through an environmentally responsible process and engineered for long-term durability, the composite machine body is the backbone of Eagle’s speed, precision, and reliability—improving parts per hour, reducing cost per part, and ensuring stable, safe operation throughout the machine’s lifetime.

Cuts stay smooth during rapid direction changes and tight contours; less chatter, cleaner microfeatures, better hole quality, and lower rework.

A temperature coefficient 10× lower and high thermal capacity minimize drift as ambient conditions change—so you hold precision tolerances and repeatability from morning startup to late shift.

The composite body provides a stiff, dead-quiet platform that lets linear motors do what they do best: fast accelerations with consistent accuracy.

Dual carriages on both sides of the X-axis deliver perfect strength, accuracy, and durability, maintaining geometry during high-speed moves and heavy duty cycles.

We don’t overlook a single detail. Every element of our fiber laser cutting machines, is meticulously designed to deliver the best cutting performance on the market. the composite body isn’t just a construction detail—it’s the performance engine room of Eagle’s fiber laser cuttingsystems. It turns high-speed motion into usable accuracy, day after day.

The body’s damping and stability achieve machining precision previously reserved for metrology-grade equipment. Result: tight GD&T, clean kerf, and repeatable nests.

By suppressing vibration during dynamic changes in cutting-head direction, the machine sustains speed without sacrificing edge quality —key for small features and dense nests.

Particularly ideal for thin and mid-thickness steel, stainless, and aluminum where acceleration and path changes dominate cycle time— boosting OEE and shortening takt time.

Thermal inertia and low expansion keep parts in spec when the shop warms up or cools down—fewer offsets, less babysitting, more uptime.