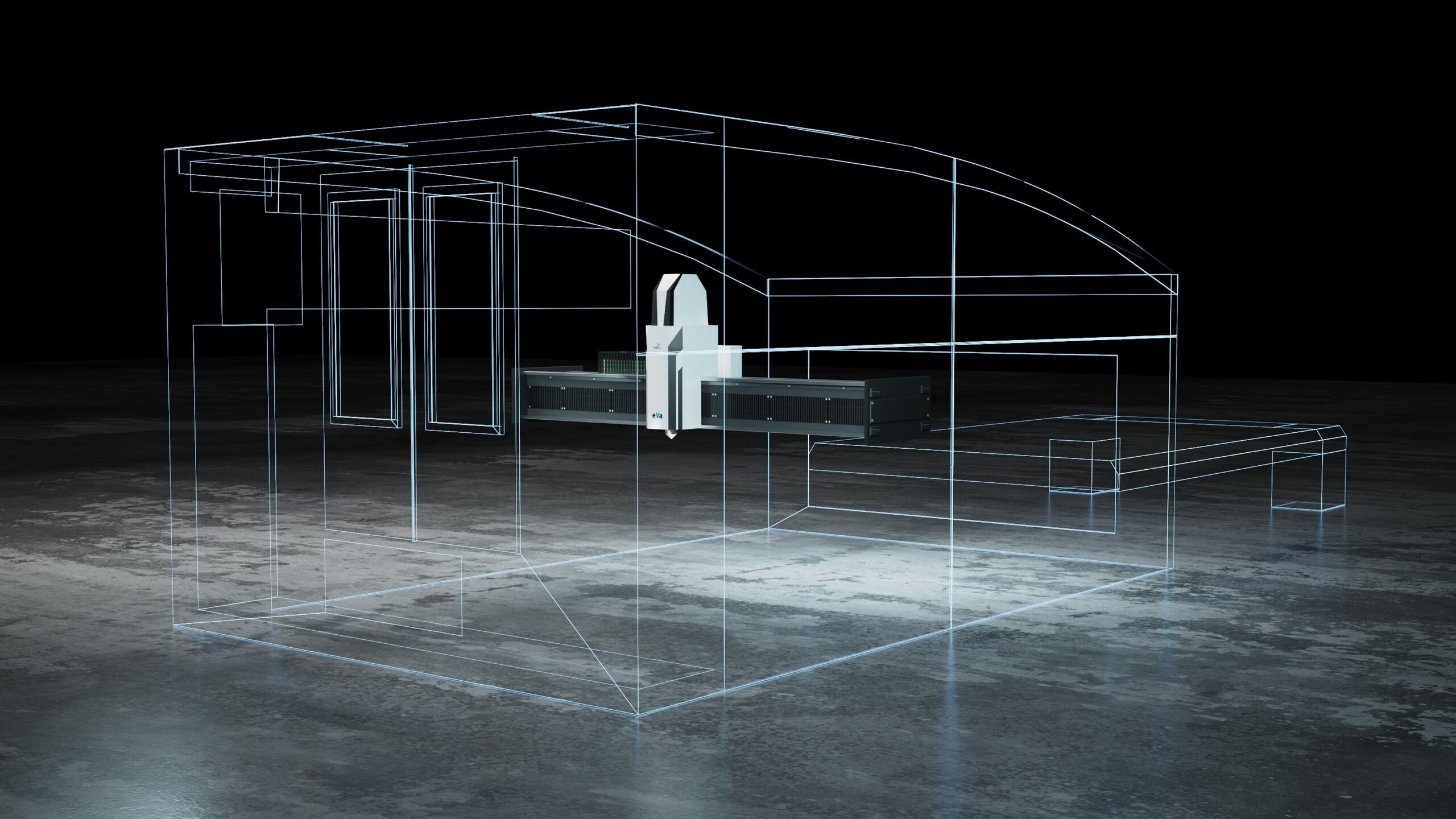

Eagle’s carbon fiber traverse combines ultra-low mass with extreme stiffness, enabling higher acceleration, faster direction changes, and precise cutting performance even at the most demanding dynamics.

To achieve true high-speed precision, moving mass must be minimized without sacrificing rigidity. That’s why Eagle fiber laser cutting machines feature a carbon fiber composite traverse, a material borrowed from aerospace and Formula 1 engineering where extreme loads, acceleration, and accuracy are non-negotiable. Carbon fiber’s exceptional strength-to-weight ratio far surpasses that of metals, allowing the traverse to remain almost perfectly rigid even at 6G acceleration, while significantly reducing mass and vibration.

By lowering inertia and enhancing structural stiffness, Eagle’s carbon fiber traverse enables faster acceleration, cleaner deceleration, and precise motion through tight contours and rapid direction changes. Advanced bridge geometry and mounting configuration further improve dynamic behavior, while the composite structure naturally dampens vibration and resists thermal expansion. The result is a traverse that supports ultra-fast cutting speeds with stable edge quality, consistent tolerances, and repeatable performance—shift after shift, at the highest dynamics.

The material’s strength-to-weight ratio far surpasses metals, enabling the kind of acceleration and precision you expect from aircraft wings and F1 chassis—now on your cutting floor.

Achieved through significantly reduced moving mass, allowing the drive system to accelerate faster without overshoot.

Low inertia enables rapid acceleration and deceleration through tight contours and frequent direction changes.

Low thermal expansion minimizes geometric variation as temperatures change, ensuring repeatable results shift after shift.

Materials, geometry, drives, and control loops are tuned together to maintain beam path stability at speed.

More good parts per hour without requiring micro-adjustments or slowing programs.

The same principles that keep F1 cars planted at 300 km/h keep your cut path stable at up to 6G.