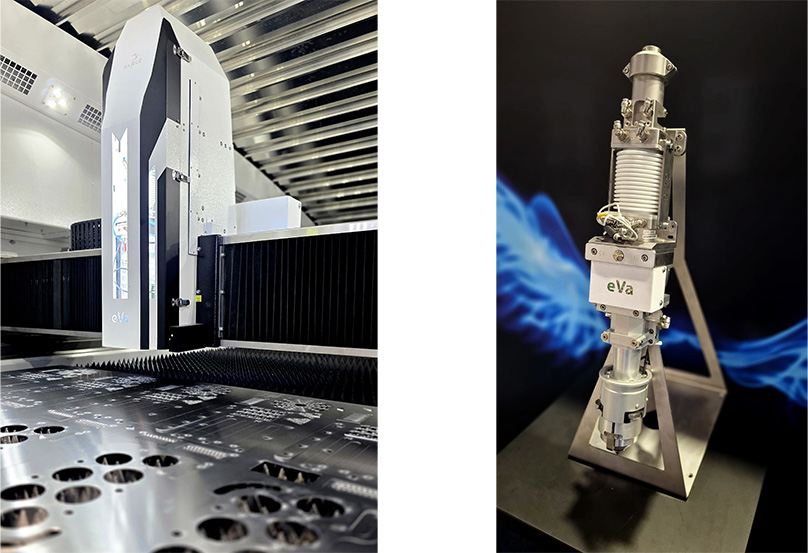

The eVa cutting head is engineered to deliver maximum reliability where it matters most. Designed to minimize contamination and wear, it transforms high laser power into stable, precise cutting with fewer interruptions, lower maintenance, and consistently high cut quality—even under extreme production conditions.

The cutting head is the most critical component of any fiber laser cutting system—especially at high power. It is responsible for controlling and focusing enormous amounts of energy with absolute precision, directly impacting cut quality, process stability, and operating costs.

The cutting head is the most critical component of any fiber laser cutting system—especially at high power. It is responsible for controlling and focusing enormous amounts of energy with absolute precision, directly impacting cut quality, process stability, and operating costs. The patented eVa cutting head was engineered by Eagle from the ground up to solve the single biggest challenge in fiber laser cutting: optical contamination. By rethinking every structural and functional detail, Eagle created a cutting head that delivers exceptional reliability, long service life, and consistent performance—even under extreme power and dynamic conditions.

Most cutting heads on the market rely on numerous optical elements and moving parts. This complexity increases wear, contamination risk, and downtime—ultimately driving up operating costs.

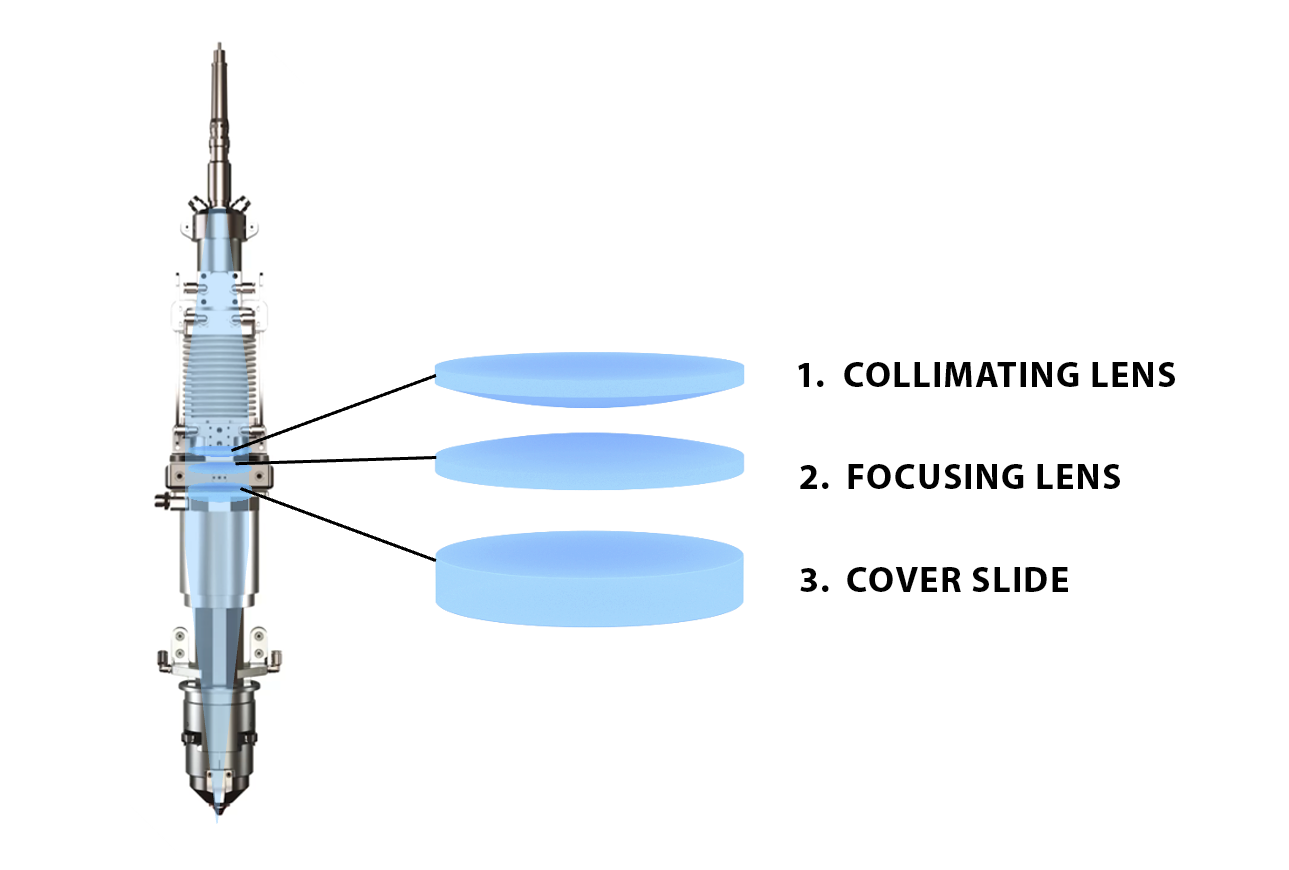

The eVa features:

By reducing the number of optical and wear components, the eVa minimizes degradation over time, lowers replacement frequency, and delivers predictable, stable cutting performance.

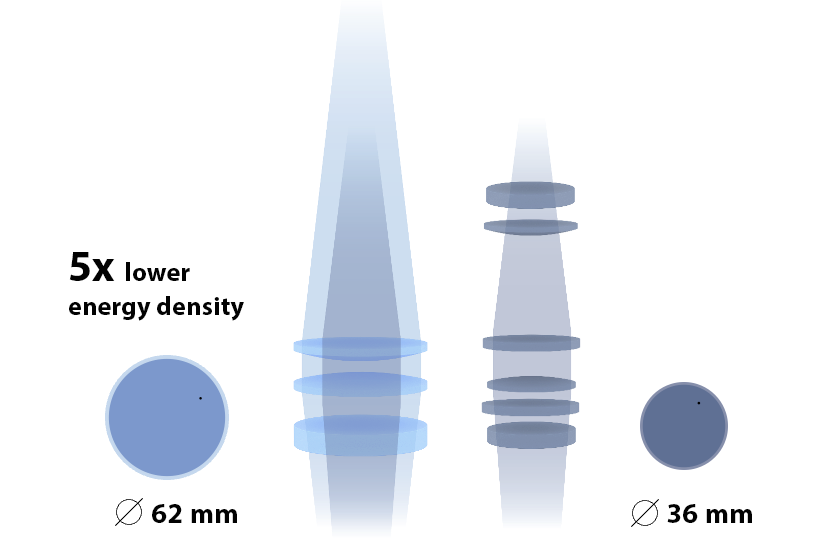

While most cutting heads use 36 mm lenses, the eVa is equipped with 62 mm-diameter lenses—a 72% increase in surface area resulting in:

The eVa cutting head is inherently better suited for high-power applications without compromising precision or reliability.

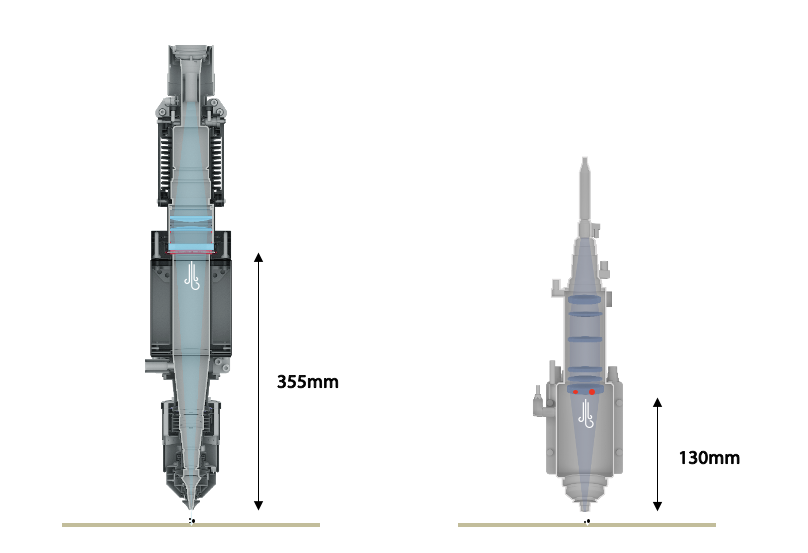

Contamination is the leading cause of cutting head failure in fiber laser systems. Eagle addressed this issue at its root. Key design innovations include:

This dramatically reduces the amount of dust and particles that can reach the optics. In real-world operation, the eVa requires up to 10× fewer cover slide replacements and is five times less prone to contamination than conventional cutting heads.

Beyond its mechanical design, the eVa integrates advanced automation features that actively protect the cutting head and extend its lifetime:

These systems work together to reduce operator intervention, prevent damage, and keep production running smoothly.

The eVa is designed to be service-friendly. Most maintenance tasks can be performed by the operator without dismounting the head or requiring an Eagle technician. This reduces downtime, simplifies ownership, and lowers total cost of ownership. Even under demanding conditions—up to 30 kW of laser power and 6G acceleration—the eVa maintains cutting stability, optical integrity, and positional accuracy.

A single eVa cutting head covers the full spectrum of materials and thicknesses processed by fiber lasers. From thin sheets to thick plates, from stainless steel to aluminum, copper, and mild steel, the eVa delivers consistent quality without compromise.

Continuously refined and upgraded by Eagle engineers, the eVa is not just a component—it is a cornerstone of Eagle’s machine philosophy and a decisive factor for manufacturers who demand reliability at the highest level.

| Design Element | eVa Cutting Head | Conventional Cutting Heads | What This Means for You |

|---|---|---|---|

| Number of optical elements | 3 optics: collimating lens, focusing lens, cover slide | Typically 6 optical elements | Fewer failure points, lower replacement costs, more stable cutting quality |

| Wear parts | Only 3 wear parts | Multiple wear-prone components | Reduced maintenance, fewer stoppages, lower operating cost |

| Lens diameter | 62 mm lenses | Typically 36 mm lenses | Up to 5× lower energy density, longer lens life, safer high-power operation |

| Nozzle–cover slide distance | 355 mm | ~130 mm | Up to 10× less frequent cover slide replacement |

| Contamination resistance | Up to 5× less prone to contamination | High contamination risk over time | Consistent cut quality and predictable production |

| Cover slide replacement frequency* | Months of continuous production (in some cases close to a year) | From daily to weekly; sometimes multiple times per shift in high-power applications | Dramatically reduced downtime and consumable costs, more predictable production |

| Maintenance approach | Serviceable without dismounting the head | Often requires disassembly or service call | Higher uptime and lower service costs |

| High-power readiness | Stable operation at up to 40 kW and 6G | Performance degrades at high power | Confidence to use full machine capability |