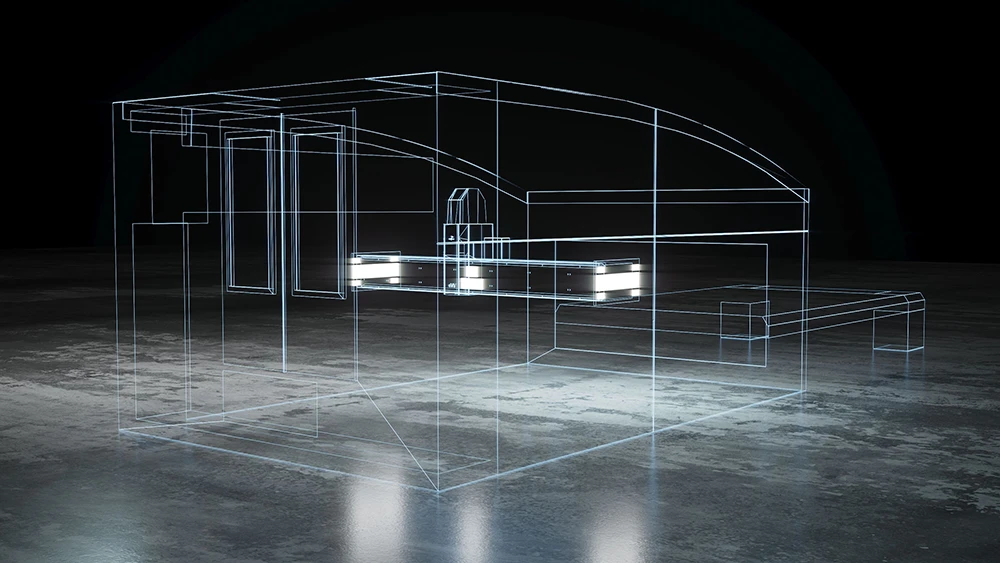

Precision starts with motion. Eagle’s linear motors deliver direct-drive accuracy, zero backlash, and the dynamic control required for high-speed fiber laser cutting.

Eagle builds both into the machine from the ground up: linear motors on all axes for direct, contactless drive, and absolute linear encoders for real-time position feedback. Unlike rotary servos with gearboxes and belts, our linear architecture removes conversion losses and mechanical play—so the cutting head goes exactly where the program says, every millisecond.

Result: Higher real-world throughput (not just headline speeds), cleaner edges, tighter tolerances, and consistent part quality from the first part to the last.

We don’t add linear technology to a conventional frame; we engineer the entire machine around it—structure, geometry, controls, and serviceability. That’s how we achieve the rare combination of speed, stability, and longevity that keeps your cost-per-part low today—and still low ten years from now.