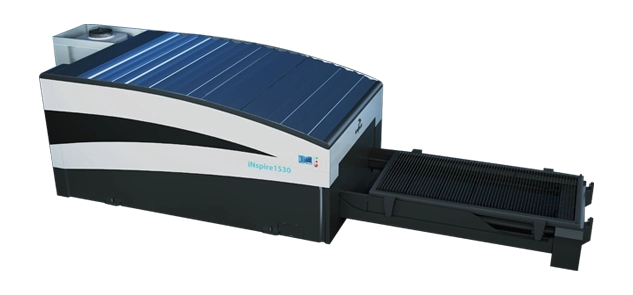

Eagle’s integrated pallet changer swaps tables in as little as 9 seconds, keeping productivity high and non-cutting time to an absolute minimum.

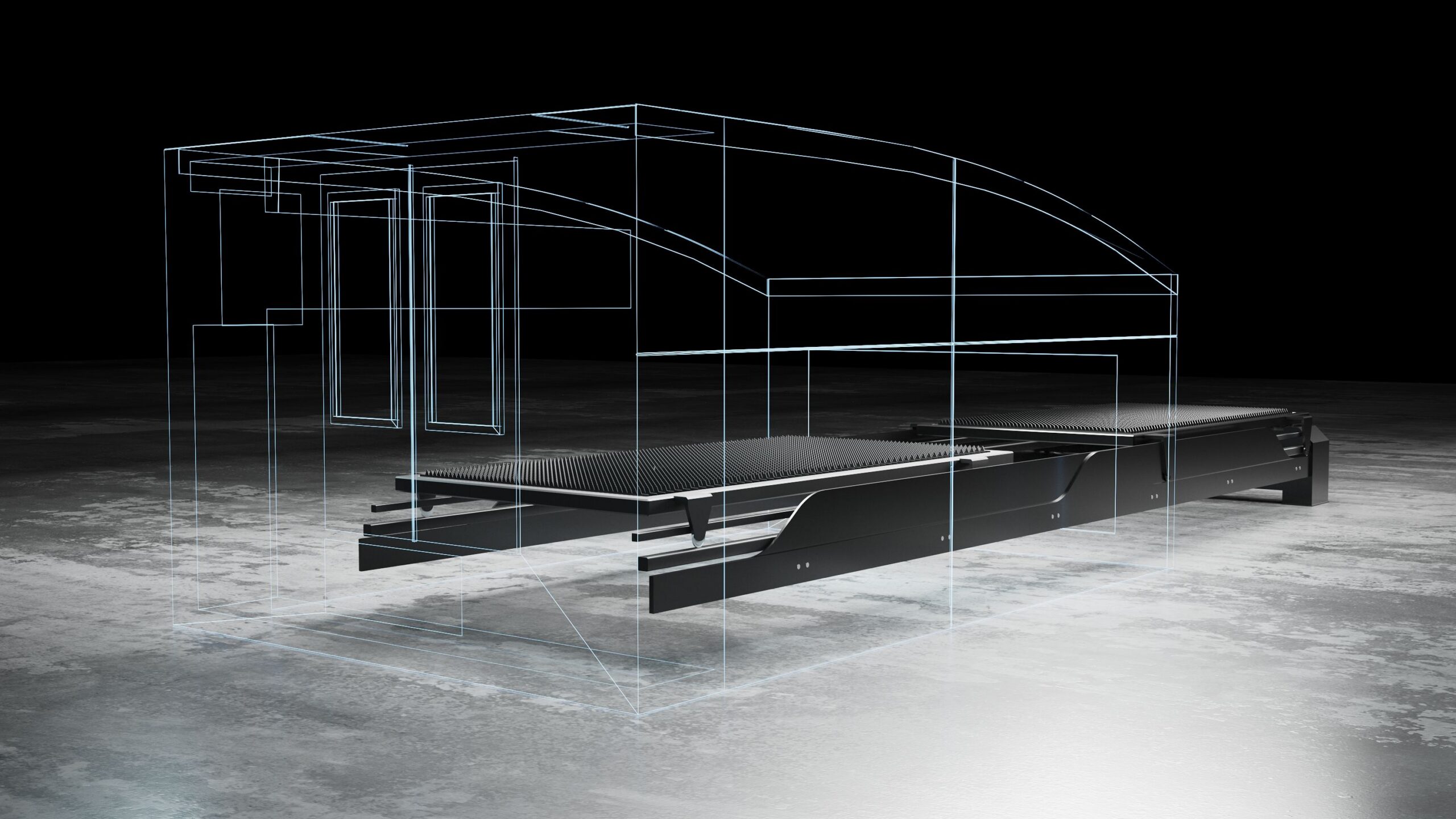

When your laser cuts in seconds, material exchange can’t be the bottleneck. That’s why Eagle engineered the fastest pallet changer on the market: fully integrated, exceptionally stable, and designed to keep pace with high-performance fiber cutting.

Our pallet changer swaps tables in just 9 seconds on the 1530 format and 13 seconds on the 2040. This ultra-short exchange time translates directly into the shortest program-to-program cycle, higher throughput, and hours of additional cutting capacity every month. The machine doesn’t wait. It cuts.

Most pallet changers are add-ons; ours is integrated directly into the machine body. By designing it as part of the core structure and eliminating hydraulics, we achieved a unique combination of speed, rigidity, and simplicity. The result is clear: more good parts per shift, fewer interruptions, and a machine that never needs to “catch up” after a swap.

Every second between programs is non-cutting time. In high-volume production, those seconds quickly add up to lost parts, missed deadlines, and reduced margins. By collapsing the material exchange window, Eagle ensures the laser spends its shift cutting, not waiting.

9 s (1530)

Fewer components, less maintenance, instant response.

Maximum rigidity, perfect alignment.

Stable, repeatable exchange even with thin sheet.

The head resumes cutting without recentring.

More cutting hours per shift with no productivity loss during changeovers.

Reducing pallet-swap time from around 40 seconds (the market average) to Eagle’s 9-second pallet changer gives you back production hours you can directly turn into margin. The example below illustrates how much time you save with Eagle’s ultra-fast exchange compared to a standard 40-second system, assuming 20 pallet changes per 8-hour shift.