GMB -

Italy

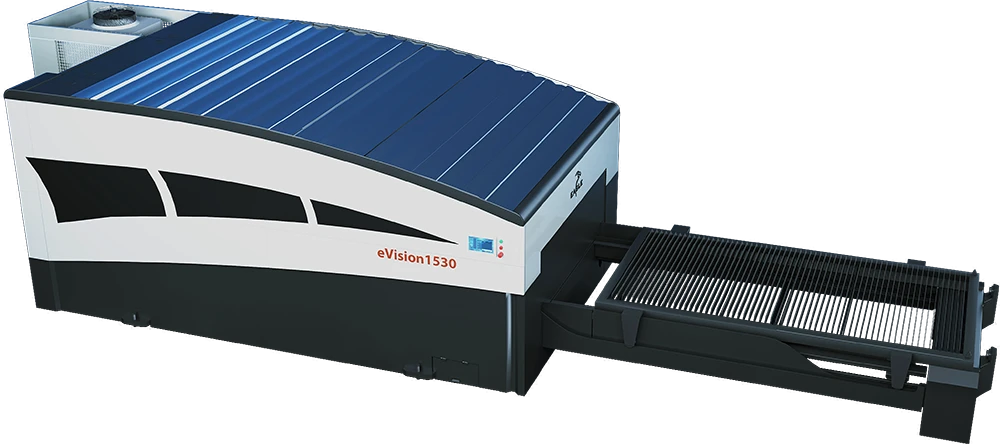

Eagle iNspire 20kW

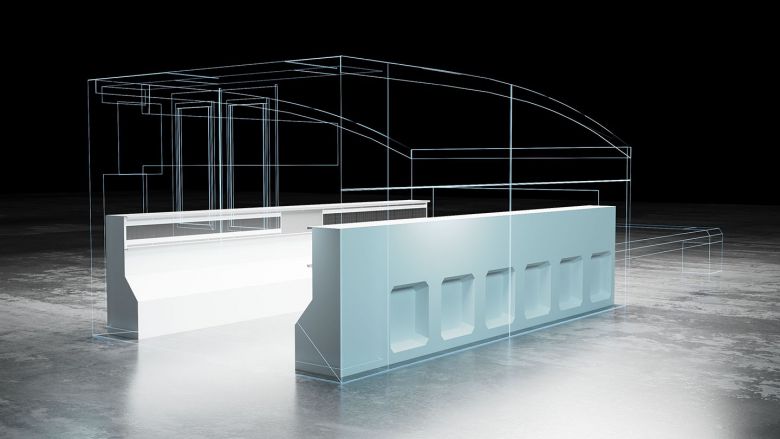

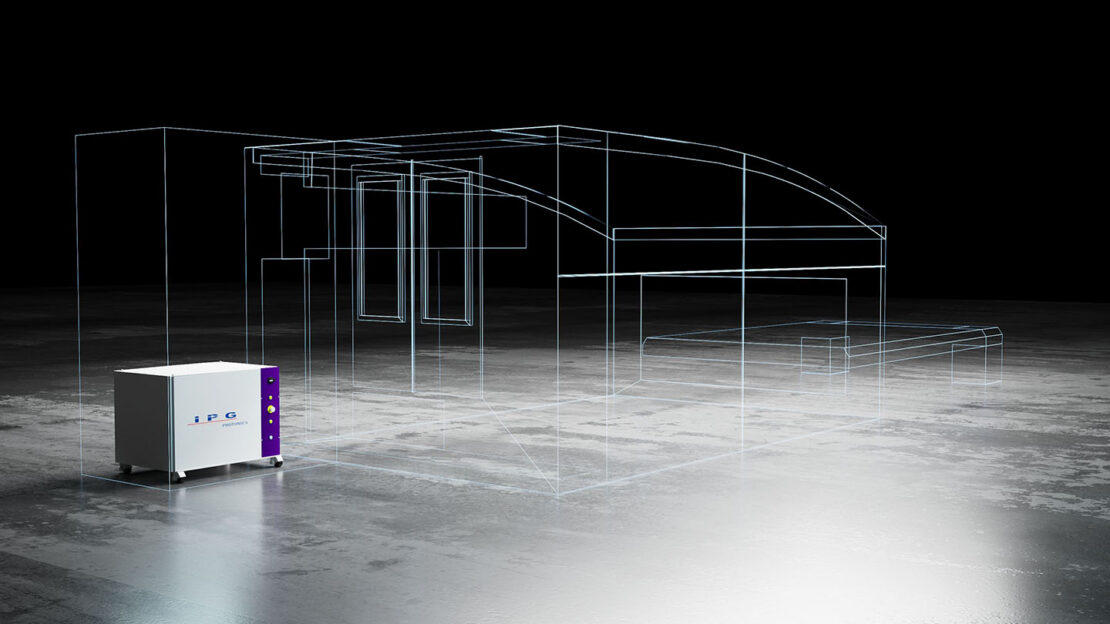

““Eagle’s cutting head incorporates advanced technical solutions that surpass those offered by other manufacturers. Additionally, the linear motors enable it to achieve remarkable accelerations of up to 6G, positioning speeds of 350 metres, and cutting speeds of up to 150 meters.”