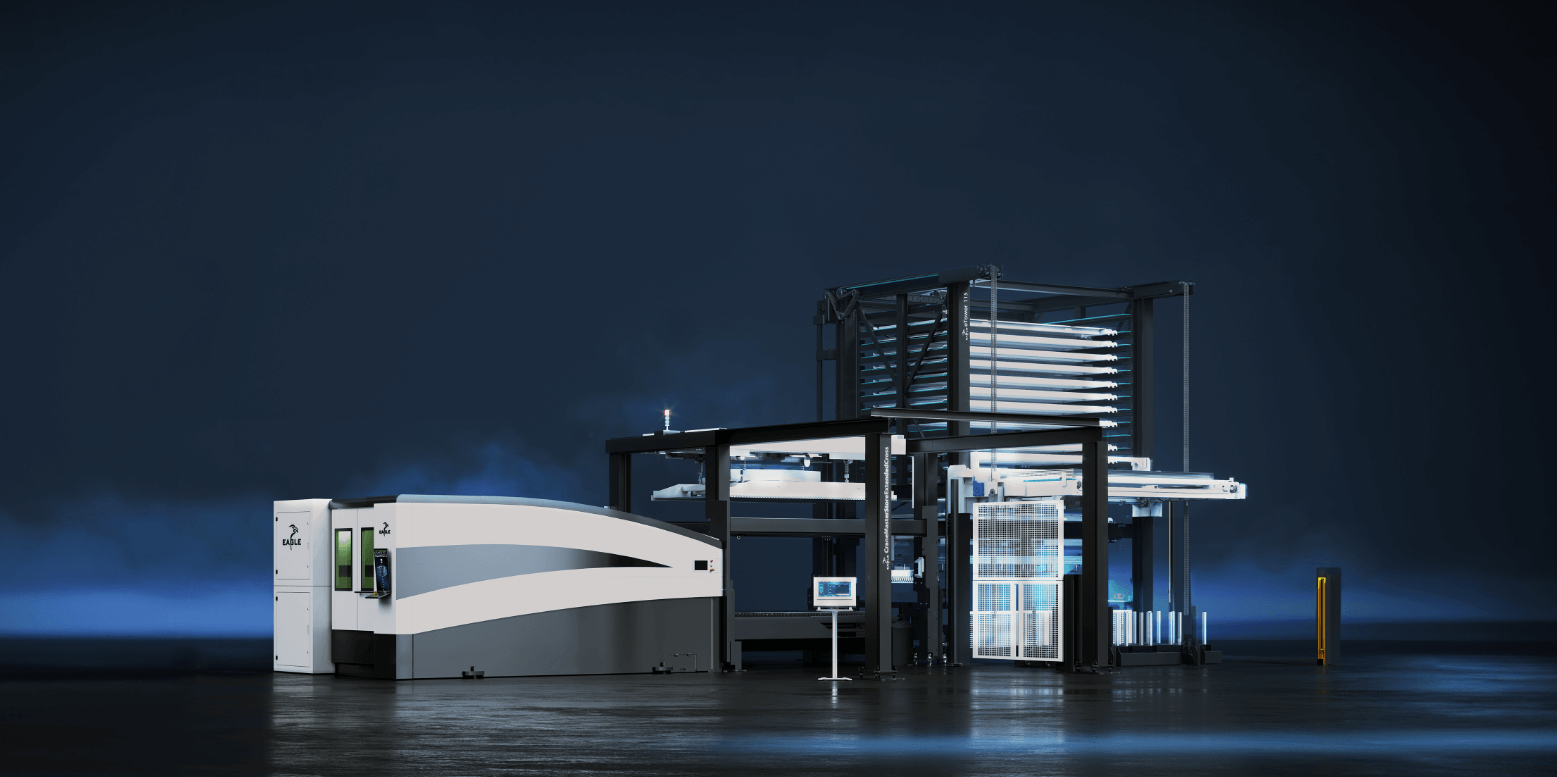

Increased Productivity and Efficiency

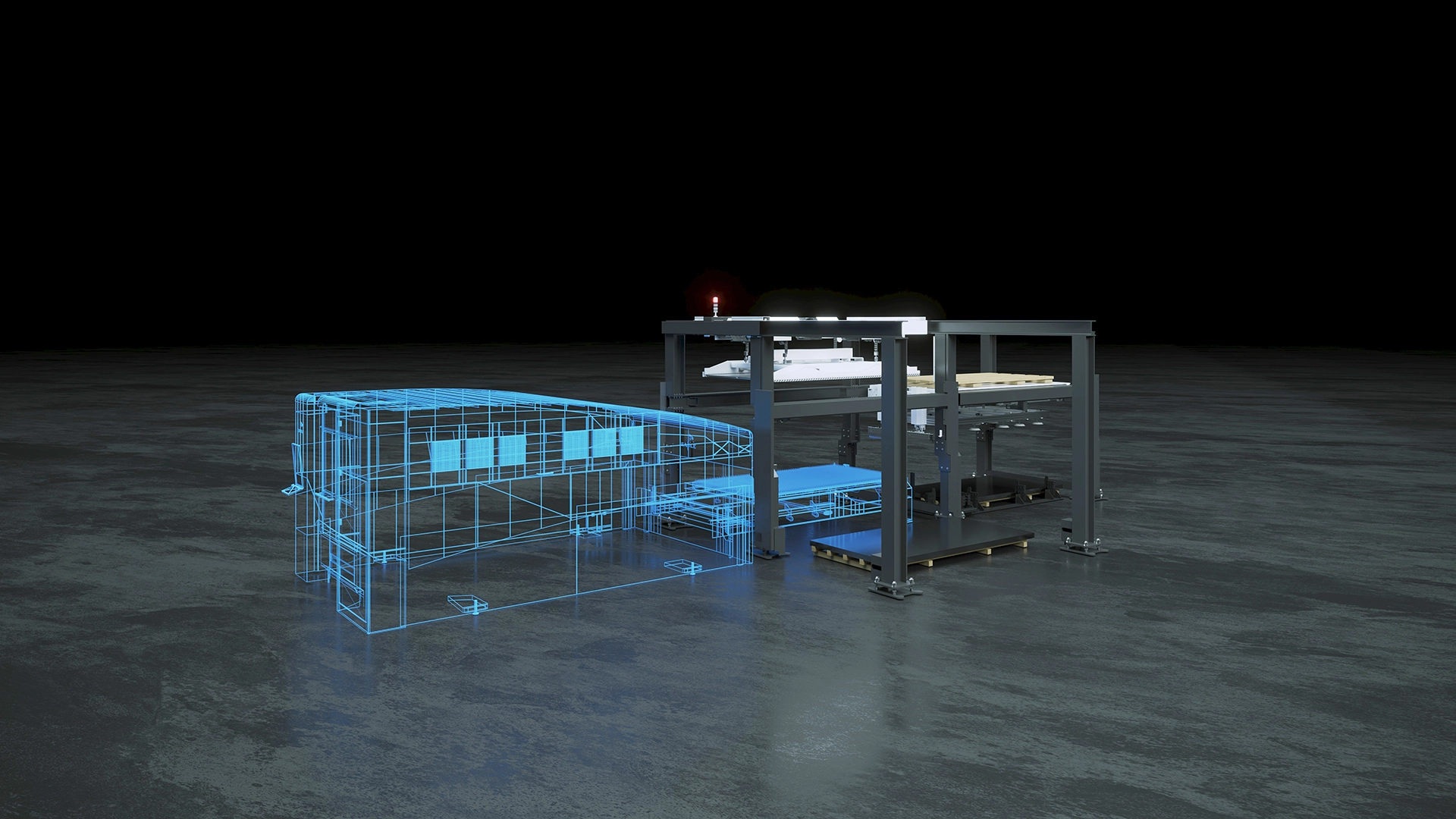

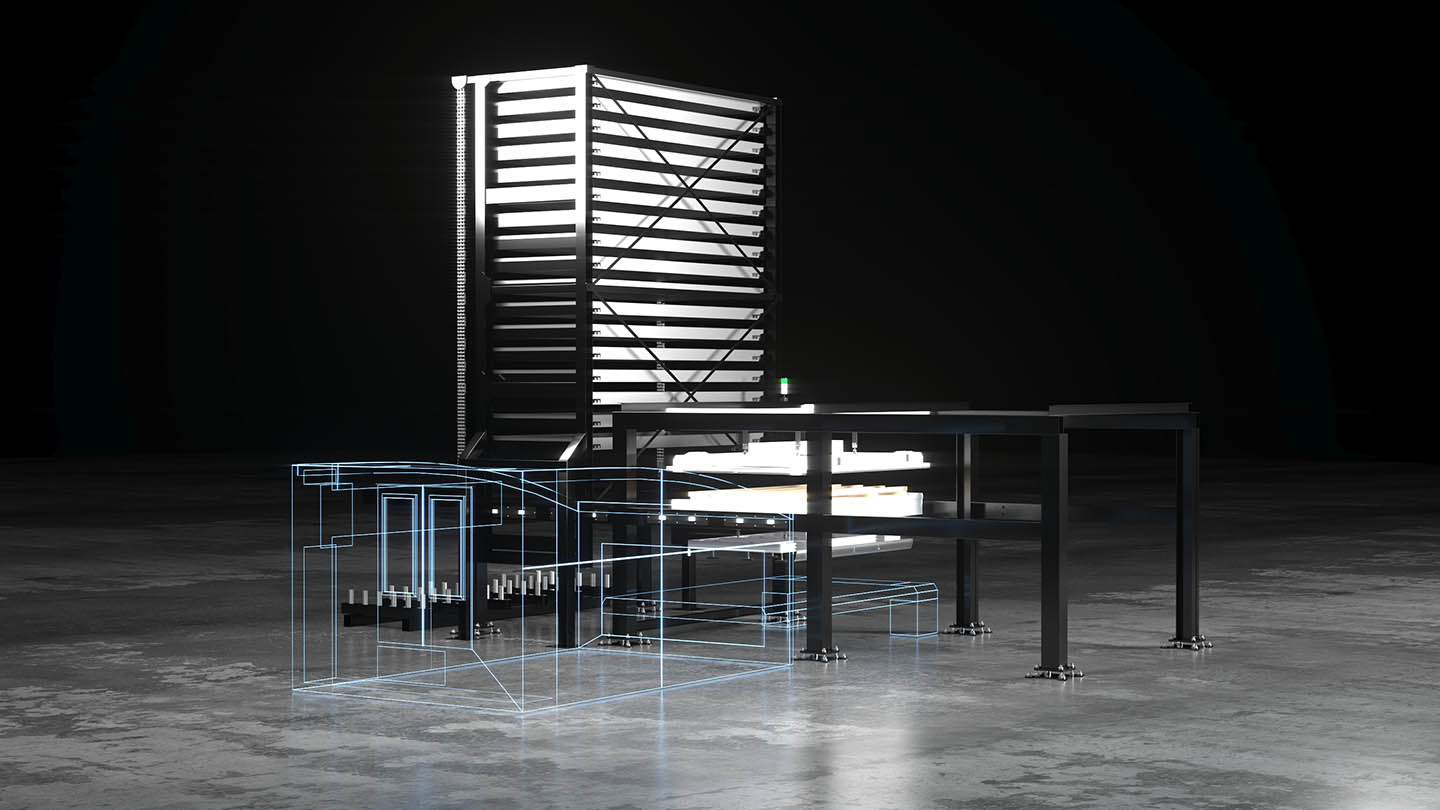

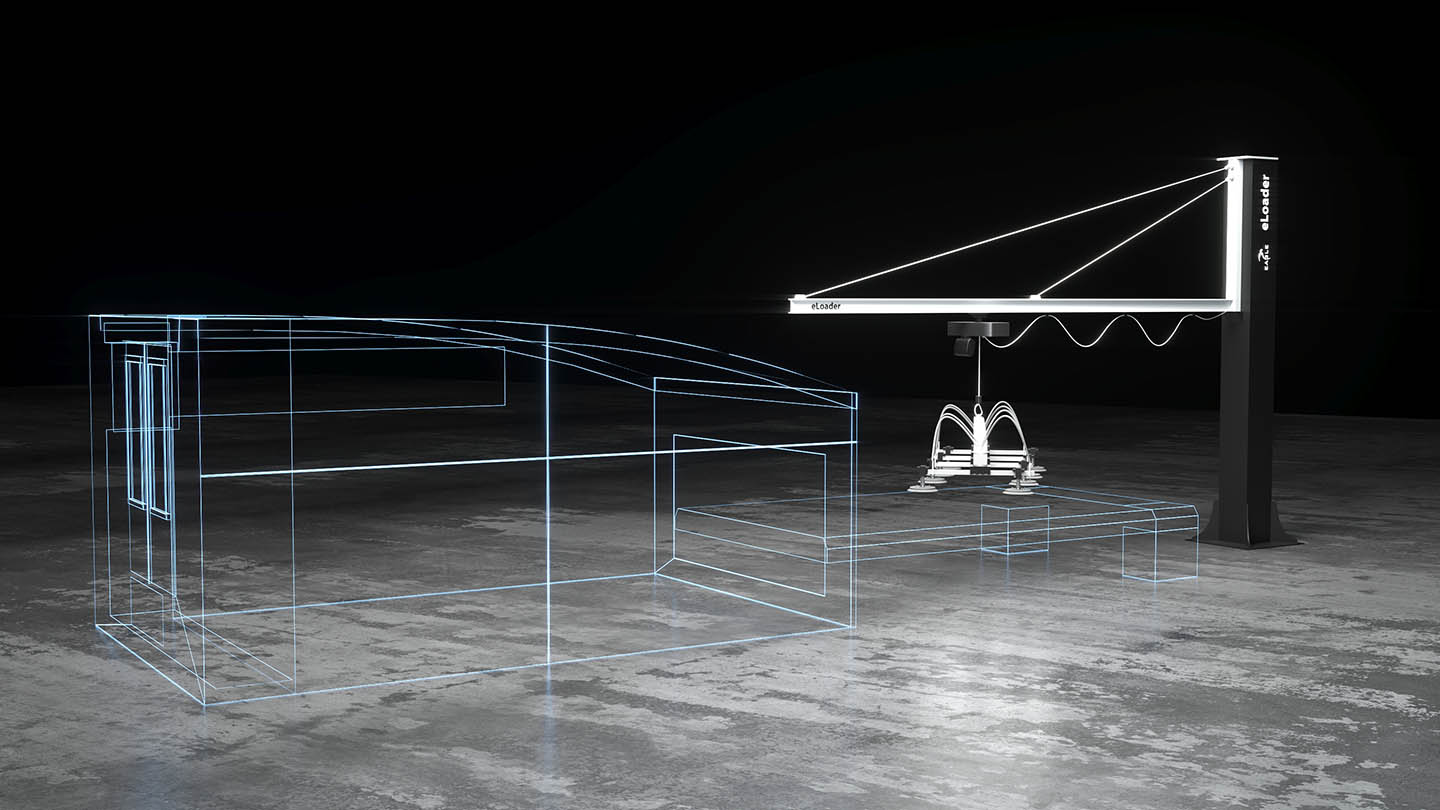

Material handling for laser cutting enables continuous, unsupervised operation allowing you to fully exploit your machine’s cutting capabilities. Swift laser cutting automation systems for loading, unloading, storage, and sorting lead to higher productivity and faster lead times, reducing your cost per part and boosting profitability.