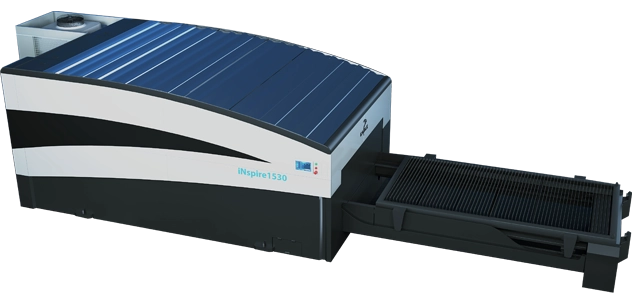

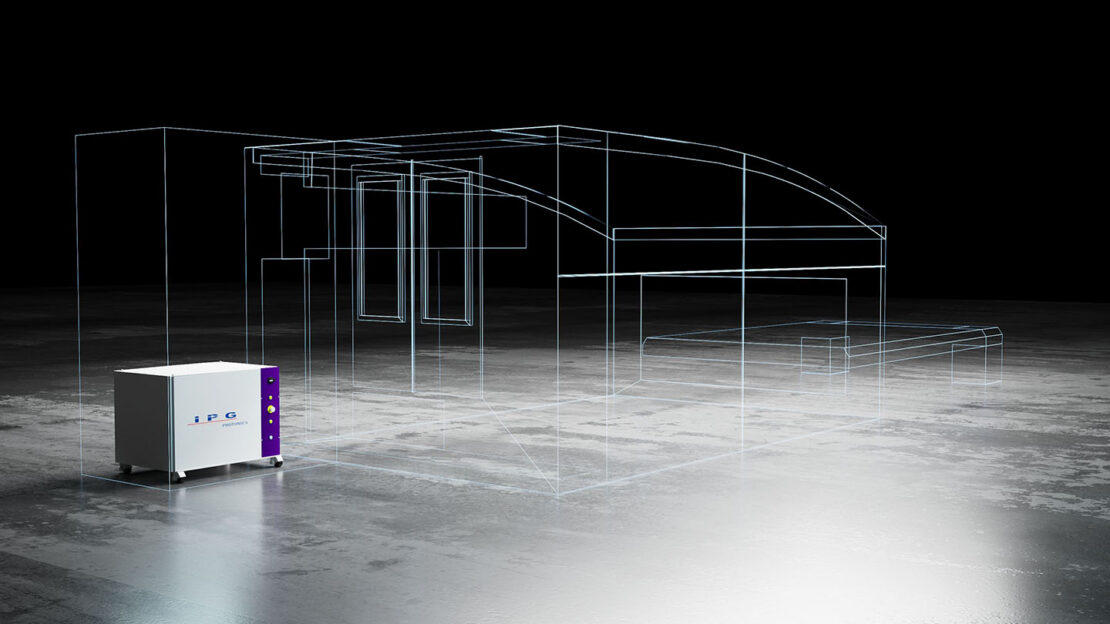

iNspire: High-speed fiber laser cutting for maximum throughput

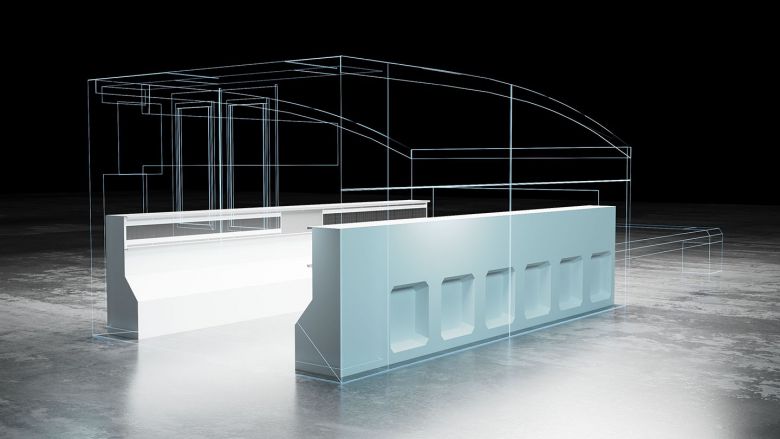

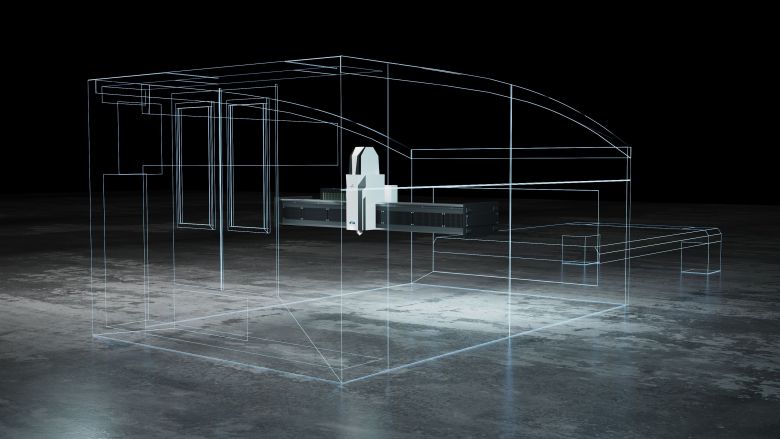

Built for speed and proven to boost profits, the Eagle iNspire combines high-power fiber laser cutting (up to 40 kW) with up to 6G acceleration, linear motors, a carbon-fiber traverse, and an ultra-fast pallet changer to maximize parts per hour and achieve the lowest cost per part. Engineered for rock-solid 24/7 reliability and full Industry 4.0 connectivity, the iNspire integrates seamlessly with Eagle Automation systems to deliver uninterrupted, high-performance production.